|

|

|

|

|

MAKE CUSTOM HATS FOR YOUR MINISTRY

Make Your Own Custom Hats Like A Professional

by David Goebelbecker, Kidco Labs

Most iron-on transfer materials provide instructions for ironing onto a T-shirt. This is relatively

easy because a shirt can be stretched flat onto any surface to receive the transfer art. Hats are seldom,

if ever mentioned, because they differ so much in size and material. They are also a challenge since it is

difficult to get the surface flat enough to iron on the material without wrinkles and creasing—difficult,

that is without a system.

We have found a method that works well for us for small batches of hats. It may seem a little bit "jerry-rigged",

but the results are very good. If you have never made hats or T-shirts before, you will want to allow yourself

ample time to test the transfer material and process to make sure you feel comfortable with the results. But

with a little practice and determination, you'll find that it's not as intimidating as you thought once you

get the hang of it.

If it is your first time making hats or using transfer materials, you will need to leave yourself a large block of time

to experiment first, so that you can work without feeling rushed. Like the

T-shirt instructions on this site,

it will require a little testing, a little thinking and a lot of patience.

PREPARING THE MATERIALS

We have supplied an overview of the process we use below along with some illustrations to help demonstrate

the method that works well for us. Our hope is that you find these instructions helpful and are as pleased

with the finished product as we are.

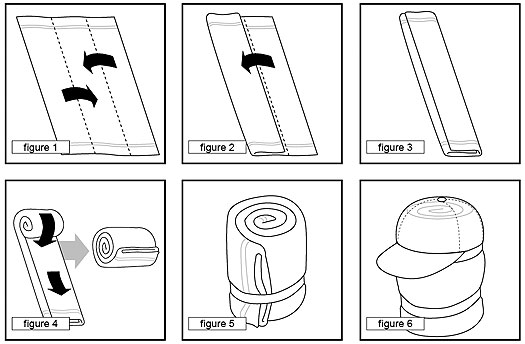

You will need a large beach size towel, or two smaller bath towels. Lay the towel(s) out on a flat surface,

like a table or the floor. [See figure 1 below.]

Next, you will want to fold the towel(s) in thirds lengthwise and roll it up as tightly as you can. It should

feel very solid when squeezed and be about the roundness of a head. This will become a form that you will be

placing the hats onto to hold them in place while ironing the logo onto the front. [See figures 2–5 below.]

Test the size by taking one of the hats and placing it over the towel. You will want to unfasten or loosen the back

of the hat to allow you to pull the hat over easily. Once the hat is in place, press on the area where the

transfer will go. It should feel solid and smooth, leaving little room for the hat to move around.

Tape the bottom of the towel to prevent it from unrolling during use. If you are planning to make a large

quantity, you can make several towel forms so that you can allow a hat to cool on one while working on another.

It saves a lot of time. [See figure 5 & 6 below.]

Note: If you are using two bath towels, you may only need to fold the towel in half. Follow the rest of the steps

and once it is tightly rolled to the right roundness, tape the bottom as shown in figures 5 & 6.

|

|

|

|

|

|

|

|

|

A WORD OF CAUTION

The following steps will be followed repeatedly as you make your finished products (your custom hats).

Before you start using good materials, you will want to make sure that you do a few tests. Read the instructions for

the transfer material with regard to iron temperature settings and time that heat should be applied. Use an old hat or

scrap material to run a few tests for time and temperature. We found that using an iron set just under full heat for about

20-30 seconds with the steam setting "OFF" gave us the best results. It's a good place for you to start your testing.

If your iron is set too high or you apply heat for too long, the logo will burn or start to look yellow. If you are using

too low of a temperature or too little time, the logo will be loose in places or have air bubbles appear underneath.

These will cause the transfer to detach in time. By applying more heat or lengthening the time heat is applied, you can

easily fix this problem. You will need to find the balance between the two that suits the materials you are using.

When making hats, one helpful tip we found is that by moving the iron slowly in a circular motion over the full decal area,

the heat was better distributed so that all areas received equal heat. You will also need to apply pressure to the iron to

make sure that the decal is pressed tightly against the material so that no gaps or creases can form.

|

|

|

|

|

|

|

|

|

IRONING ON THE LOGOS

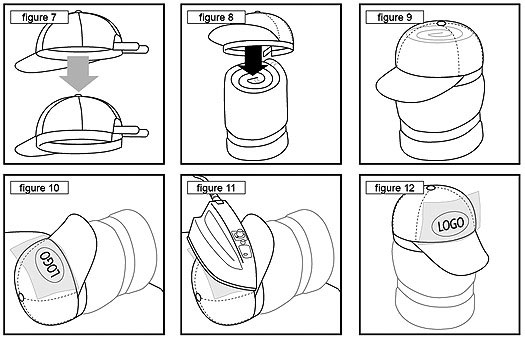

Inside a hat, there is a headband liner that will need to be pulled inside out before placing the hat onto the towel form.

Keep the back fasteners open while you are doing this and place the hat onto the form. You will once again want to push

as much of the towel form into the hat as possible to create a solid smooth surface in the front of the hat.

[See figures 7-9 above.]

You are now ready to transfer the logo. Place the hat on the towel form on a hard flat surface, like a table or the floor.

(We use an ironing board because we can adjust the height of the surface and it's already where the iron is.)

IMPORTANT: Use the same iron settings and time that was used during your test set up mentioned above.

If you have not completed a time and iron temperature test, do so before you proceed to minimize waste.

Also, make sure that the steam setting for the iron is OFF!

Place the trimmed logo onto the front area of the hat and visually position it where you want it. If you are using the

dark T-shirt transfer material, you will have had to remove the backing and placed the decal face up on the hat.

[See figure 10.]

NOTE: The illustration below shows how the finished logo should look once you have trimmed out the edges. You will need to be more

careful with the transfer sheets for dark materials because this edge will be visible and outline the logo or image. To save time,

we recommend trimming out all of your logos ahead of time.

|

|

|

|

|

|

|

|

|

Next, you will need to carefully place the ironing sheet over it so it doesn't shift position. Then, carefully place

the heated iron over the ironing paper and slowly move it in a circular motion, pressing firmly and making sure that

you are covering as much of the logo with the iron surface as possible. [See figure 11.]

Once you have applied heat for the time that you determined during your tests, remove the iron and allow the transfer

time to cool before removing the ironing sheet and your hat is ready to wear. [See figure 12.]

|

|

|

|

|

|

|

|

|

|

PART OF THE PACKAGE

These instructions have been adapted from the Kidco Labs curriculum materials. In each series, we provide a resource CD

with logo sheets of each series logo in PDF format for you to use. We believe that every ministry should have a

chance to make a great impression on the community and using hats and t-shirts are a great way to get the message out

about your ministry and what you are doing.

|

|

|

|

|

|

|

|

|

Articles Overview

Powerful Praise and Worship

The Science of Leading Great Games

Creating An Effective Environment

Leading Children To Christ

Creating Custom T-shirts

Making Custom Hats

Using Fonts Effectively

Add A Little F.U.E.L. To Your Lesson

Is Your Ministry Running On All Cylinders?

Live. Laugh. Learn.

Resources Overview

Leader Resources

Game Zone

Worship Resources

Download Center

Articles

|

|